Introduction: In the context of large-scale production of new energy vehicles, vehicles awaiting delivery need to maintain a fully charged state during the pre-delivery phase to meet end-user demand. However, traditional charging methods rely on the static layout of fixed charging piles and manual plugging and unplugging of charging guns, resulting in insufficient flexibility in charging resource scheduling, high dependence on manpower, and low equipment utilization during nighttime/low-load periods. These methods are ill-suited to the intelligent and low-carbon production management requirements of modern automobile manufacturing plants.

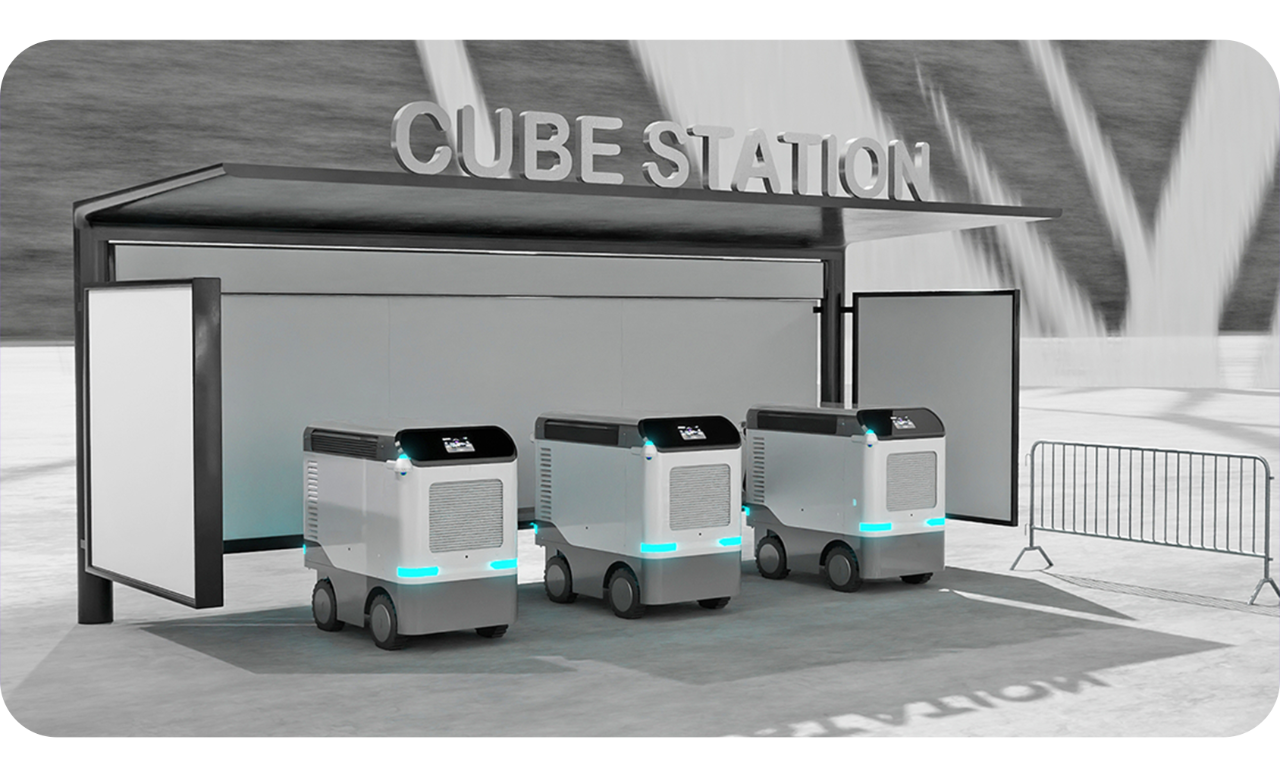

Shitu Technology's newly launched CUBE05 AUTO and CUBE05 AUTO MAX intelligent mobile energy storage and charging robots focus on the core scenario of "energy replenishment during the pre-delivery phase of new energy vehicles." Through the integration of "mobile energy storage and charging + photovoltaic collaboration + intelligent scheduling," they restructure the energy replenishment process at vehicle manufacturers, providing precise, efficient, and low-carbon energy replenishment services for vehicles awaiting delivery, ensuring that every new energy vehicle enters the delivery stage in optimal condition.

I. Scenario Needs Analysis: Pain Points in Energy Replenishment During the Pre-Delivery Phase of New Energy Vehicles

In the mass production system of new energy vehicles, vehicles must undergo testing and debugging before being temporarily stored in the pre-delivery area until the delivery process is completed. During this phase, vehicles need to be kept fully charged to ensure a good user experience. However, existing charging methods face multiple challenges:

1. Limited fixed charging station resources: Physical layout is fixed and the number is limited, making it difficult to dynamically match the random charging needs of vehicles in waiting areas;

2. Inefficiency bottleneck of manual operation: Reliance on dedicated personnel for charging gun insertion/removal, vehicle dispatching, and charging status monitoring results in high labor costs and low standardization;

3. Insufficient energy dispatch flexibility: The coexistence of idle charging resources at night/low load periods and concentrated demand during peak daytime periods puts significant pressure on the power grid and keeps overall electricity costs high;

4. Difficulty in achieving green and low-carbon goals: Traditional charging methods are highly dependent on the power grid, making it difficult to effectively integrate renewable energy (such as photovoltaic power) and resulting in weak synergy with automakers' ESG (Environmental, Social, and Governance) development goals.

The development of the CUBE05 AUTO series by Shitu Technology addresses these industry pain points by designing a mobile, intelligent, and low-carbon charging solution to fill the "charging efficiency gap" in the new energy vehicle manufacturing scenario.

II. Core Function Analysis: Technological Breakthroughs and Scenario Adaptation of Intelligent Mobile Energy Storage and Charging

1. Photovoltaic Collaboration + Peripheral Pre-charging: Building a Green Energy Supply Chain

The system supports deep integration with the vehicle factory's rooftop distributed photovoltaic system. The mobile energy storage robot prioritizes charging and energy storage using photovoltaic power. Through the intelligent energy management system (EMS), the robot can autonomously store green electricity in the area surrounding the factory and convert it into "mobile energy packs" for vehicles waiting to depart. This design reduces dependence on grid power supply, alleviating the power load pressure on fixed charging piles; on the other hand, through the efficient use of renewable energy, it significantly reduces carbon emissions in the overall energy supply process of the vehicle factory, achieving the goal of low-carbonization across the entire "production-energy supply" chain.

2. Cloud Scheduling + Autonomous Driving: High-Precision Path Planning and Autonomous Vehicle Finding

Based on a cloud-based intelligent scheduling platform, the CUBE05 AUTO series can collect the real-time coordinates of vehicles in the waiting area, their current power status, and charging priority requirements. It dynamically generates the optimal energy supply path through a multi-objective optimization algorithm. The robot is equipped with a high-precision navigation and autonomous obstacle avoidance module, enabling it to autonomously plan its route and accurately reach the target vehicle's parking position in complex automotive factory environments without human guidance. This capability breaks through the spatial limitations of traditional fixed charging piles, realizing "on-demand allocation" and "instant response" of charging services.

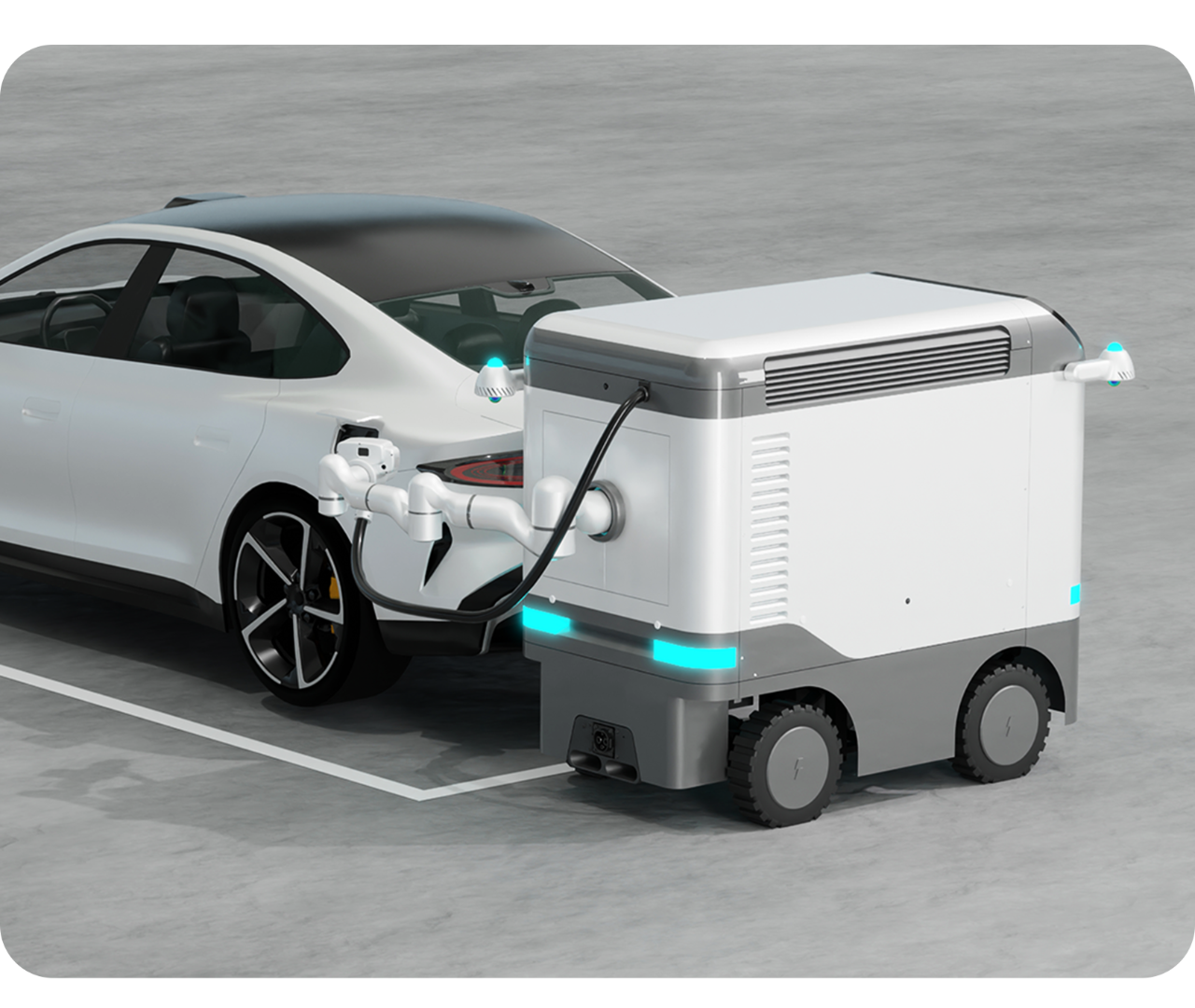

3. 6-Axis Robotic Arm + Seamless Charging: Automated Charging Operation Adaptable to All Vehicle Models

Addressing the significant differences in charging interface locations among new energy vehicles (such as deviations in charging port height, angle, and spatial layout across different brands/models) and the industry characteristics of frequent model iterations, the robot integrates a high-precision 6-axis robotic arm system. Combined with machine vision recognition (with sub-millimeter accuracy) and force control feedback technology, it can automatically complete the precise positioning, grasping, insertion, and removal of the charging gun. Charging docking errors are controlled within the millimeter range, and it is compatible with the charging interface standards of mainstream new energy vehicle models, achieving a seamless "stop and charge" charging process without human intervention. This design allows a single robot to replace 3-5 dedicated charging operators, significantly reducing labor costs for automotive factories and improving operational consistency.

4. 24-Hour Response + Peak-Valley Adjustment: Efficient Energy Management Around the Clock

For vehicles awaiting delivery in off-site distribution areas (such as temporary parking lots and logistics transfer stations), the CUBE05 AUTO series supports a 24/7 uninterrupted operation mode: during peak daytime charging demand periods, priority is given to quickly recharging vehicles for urgent delivery; during low-load nighttime periods, charging and energy storage tasks are automatically performed, and energy usage costs are optimized through peak-valley electricity price differences (potentially reducing electricity expenses by up to 30%-50%). This mode balances the timeliness and economy of recharging, adapting to the dynamic operational needs of automakers in various scenarios.

III. Product Matrix Expansion: CUBE05 AUTO MAX – A Super-Fast Charging Solution for High-Power Demands

For the special requirements of high-end models or urgent delivery orders for recharging speed, CUBE05 AUTO MAX Enhanced Edition is available from Shitu Technology. This version integrates a high-power DC fast charging module on top of the basic functions, supporting higher charging power output (specific parameters are adapted according to the vehicle's electrical architecture). The charging efficiency is more than 3 times higher than the standard version, and the vehicle can be quickly recharged in 15-30 minutes (the regular version takes 30 minutes to 2 hours), meeting the needs of efficient delivery scenarios of "charge and fire immediately".

IV. Customer Value Summary: Multi-dimensional Benefits Driving Automakers' Intelligent Transformation

Cost Optimization: Reduces the need for dedicated charging staff, lowering long-term labor costs; by replacing some grid power with photovoltaic green electricity and profiting from peak-valley electricity price arbitrage, overall costs decrease by 50%-80%;

Efficiency Improvement: Shortens refueling time per vehicle (30 minutes-2 hours in standard mode, 15-30 minutes in MAX version), improving vehicle turnover efficiency in waiting areas and supporting higher production capacity delivery schedules;

Intelligent Adaptation: Cloud-based scheduling systems and autonomous driving functions do not require modifications to existing automakers' infrastructure, supporting rapid deployment and plug-and-play functionality, with significant compatibility with flexible production lines;

Green and Low-Carbon: The photovoltaic energy storage synergy model reduces reliance on fossil fuels, lowers carbon emissions during refueling, and helps automakers achieve their ESG strategic goals and carbon neutrality commitments.